A New Phase: Why Is Global Capital Pouring Into Syria’s Cement Industry?

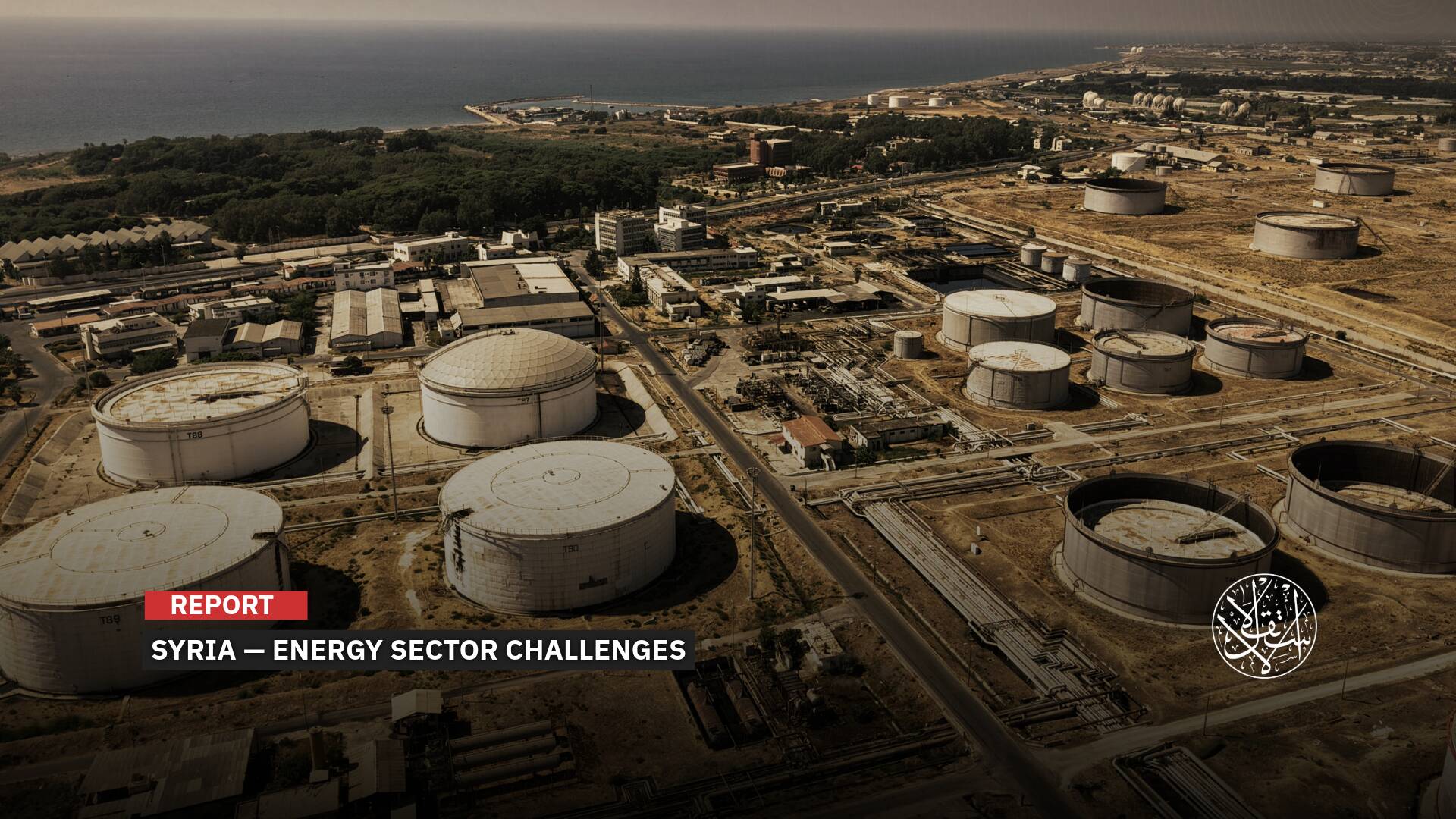

Cement production is limited to state-owned plants and a single private factory.

As investment interest surges in postwar Syria, cement production is drawing growing attention from international companies eager to secure contracts, with the sector poised to play a central role in the country’s reconstruction.

The True Face of the Sector

Cement production in Syria has declined in recent years due to a lack of funding, outdated factories, missing spare parts, and the closure of many plants as a result of Western sanctions. Now, however, a new phase could pull the sector out of its stagnation.

Mahmoud Fadila, Director General of the General Company for Cement and Building Materials Marketing, “Omran,” confirmed that the government has received more than 15 offers from Arab and foreign companies to invest in cement and building materials.

On 29 July 2025, Fadila said that the Ministry of Economy and Industry, in cooperation with the cement company, had prepared since early July a special terms document for investing in the cement mills of the Tartus Cement Plant. The document sets out the technical, legal, and financial standards for investment.

He added that the company held an introductory session at the Adra Cement Company headquarters in rural Damascus, attended by directors and representatives of interested companies. Representatives from 15 companies based in Syria, Saudi Arabia, Jordan, Lebanon, Iraq, Turkiye, and Germany participated. They expressed interest not only in the mills of the Tartus plant but also in other plants to be offered later.

The Syrian government has decided to halt local production of clinker (the raw material for cement before grinding) because of its high production cost, rising fuel prices, and outdated production lines in existing plants. As an interim measure, Syria is importing clinker from Saudi Arabia, Egypt, Algeria, and Iraq at a cost lower than producing it locally, thereby reducing the final product price.

The fall of Bashar al-Assad’s regime on 8 December 2025 revealed the true extent of destruction in towns and neighborhoods targeted by the regime’s scorched-earth tactics. Before the regime’s collapse, cameras rarely captured the full scale of the damage. Liberation of the country allowed engineering teams to conduct preliminary assessments, showing that cities across Syria are in total ruin, with essential services exhausted.

A survey by the United Nations Institute for Training and Research (UNITAR) assessed destruction in about 16 Syrian cities and towns caused mainly by Assad’s forces and their allies. Aleppo topped the list with around 36,000 destroyed buildings, followed by Eastern Ghouta in rural Damascus with 35,000. Homs ranked third with 13,778, then ar-Raqqah with 12,781, Hama with 6,405, Deir ez-Zor with 6,405, and Yarmouk Camp with 5,489 destroyed buildings.

Keeping Pace with Agreements

The government is now moving to make optimal use of cement production sites that face shortages in raw materials, especially given the significant gap between supply and demand. Import bans and reliance on public-sector plants plus a single private plant have driven prices sharply upward.

Existing plants are located in Adra (Rural Damascus), Ar-Rastan (Homs), al-Muslimiyah (Aleppo), and Tartus. Cement is sold in 50 kg bags at $107 per ton, or in bulk at $105 per ton, distributed to all provinces via dealers.

Currently, 60 percent of available cement in Syria comes from imports, while all locally produced cement is sold without affecting plant operations.

The Hama Cement Plant resumed operations on 23 February 2025, selling its product in U.S. dollars at prices its management described as “reasonable and competitive” with imported cement. The plant’s daily production capacity now reaches 3,300 tons, producing multiple types, including Portland and sulfate-resistant cement.

Even so, public demand for rebuilding remains low because of high costs. Over 90 percent of households live below the poverty line, and at least 13 million people (more than half the population) cannot access or afford enough food, according to Human Rights Watch.

Abdulhamit Akcay, vice chairman of Turkish Cement, told S&P Global Commodity Insights that the Syrian market presents a significant opportunity for Turkish cement producers, but the country's transition to stability will take time.

“There is an opportunity. The Syrian market has been an important market for Turkish cement producers in the last decade despite the war,” Akcay said in December 2024. “After the recent political developments and the regime change, there is great potential, but it is not something that will happen immediately.”

Experts emphasize the need for site-specific technical standards to increase both output and quality while reducing costs. This includes cutting imports of production materials, easing pressure on foreign currency reserves, and minimizing the drain on the public budget.

Many companies see the construction of modern cement plants in strategically located Syrian sites, built to high technical standards, as a way to supply the domestic market during reconstruction and export any surplus to neighboring countries and global markets, benefiting from Syria’s geographic location.

One study now underway proposes building a new cement plant in Aleppo with a production capacity of 10,000 tons per day, which would be a vital asset during reconstruction.

Future projects in Syria, including housing, infrastructure, airports, power plants, bridges, hotels, and industrial and tourist centers, will require vast amounts of cement. This makes balancing production with demand a critical goal.

According to Ayman Aldassouky, a researcher at Omran Center for Strategic Studies, international companies see the cement sector as a profitable investment opportunity, especially as the government moves to facilitate foreign investment.

Aldassouky told Al-Estiklal that foreign companies are rushing in because local production cannot keep up with the booming demand sparked by reconstruction. He pointed to a growing gap between supply and demand as new agreements and memoranda of understanding are implemented, particularly in construction and infrastructure. He added that some companies may also be looking to use Syria’s central location as a future export hub.

The researcher noted that the cement sector in Syria faces a shortage of skilled labor because most experienced workers have retired, others have left, and there have been insufficient hires of qualified engineers, young skilled workers, and technical, production, and administrative staff.

Sector Development

The General Company for Cement and Building Materials Marketing, “Omran,” is preparing a new roadmap to develop Syria’s cement industry by combining local expertise with international consultancy, according to the company’s Director General, Engineer Mahmoud Fadila, who spoke to the state news agency SANA.

Fadila noted that before 2011, annual demand for cement was about 8 million tons, while local production reached only 5.5 million tons. The shortfall was covered through imports.

Today, average daily cement consumption in the first seven months of the year reached 20 to 25 thousand tons, equivalent to about 7 million tons annually, while actual domestic production is only 4.5 million tons if state-run plants operate at full capacity, and the private sector currently produces just 1.5 million tons a year.

There are 11 cement plant licenses granted to investors before 2010 that were never built. The license holders have now been instructed to set clear timelines for construction. Once operational, these plants would have a combined production capacity of 40 million tons annually.

On 20 January 2025, Saudi Arabia’s al-Jouf Cement Company signed a contract with the Muhammad Shahi al-Ruwaili Contracting Establishment to supply all types of cement and clinker for export to Syria.

“Omran” is also pursuing technical cooperation agreements and staff training partnerships with several countries, alongside efforts to modernize existing plants and equip them with technology that matches global advances in the cement sector.

On 24 July 2025, it signed a joint cooperation agreement with Saudi Arabia’s Northern Region Cement Company. The deal aims to establish a comprehensive equipment overhaul plan, improve the technical skills of Syrian cement industry personnel, strengthen mechanisms for technical cooperation, and transfer expertise.

The agreement also focuses on workplace safety, industrial security, and environmental protection, with training in the latest pollution control technologies. It includes applied programs covering material grinding and technical inspections of industrial equipment.

During the Syrian–Saudi Investment Forum in July 2025, Saudi Minister of Investment Khalid al-Falih announced plans to establish more than three cement plants in Syria, with total investments exceeding 11 billion Saudi riyals.

On 23 July 2025, Syria’s Minister of Economy and Industry, Mohammad Nidal al-Shaar, and the Saudi Minister of Investment launched the Fayhaa Cement Plant project in the Adra Industrial City, rural Damascus, marking the first white cement manufacturing project in Syria.

Sources

- The Syrian Government Receives Investment Offers from 15 Arab and Foreign Companies in the Cement Sector [Arabic]

- Companies Submit Bids to Invest in Syria’s Cement Sector

- Turkish cement producers eye growth in Syria amid hurdles: association vice chairman

- Syria: Thousands of Homes Destroyed, Residents Killed, Wounded, or Displaced [Arabic]

- Syria Cancels Fees on Locally Produced Cement [Arabic]

- Fadila: Plans to Develop Cement Industry and Meet Syria’s Reconstruction Needs [Arabic]

- Cement Authority Director: Producing 12 High-Quality Cement Types in Syria [Arabic]